A Miniature Variable Compensator.

For the older

microscope stands.

By Ian Walker. UK.

Introduction.

Earlier this year I described a

simple home made variable compensator for use with crossed-polars to

make

measurements with thin rock sections and provide an insight into the

workings of commercial Berek style compensators at a tiny fraction of

the cost of those from Zeiss, Leica et al and is shown below in Fig 1. below. Using a

finely cleaved piece of mica the unit is situated on the microscope

base between the light source plus polarizer and substage. Well that's

fine I thought to myself I was pleased with the results and the overall

design but I wanted to take it one stage further and make it available

for older microscopes which use an angled stand and external light

source. To make it viable it was going to have to be a light

self contained unit with the only likely option of fitting it to the

eyepiece tube this demanded a novel approach.

Further information on the parts and materials of

the original compensator can be found by following the link at the end

of the article.

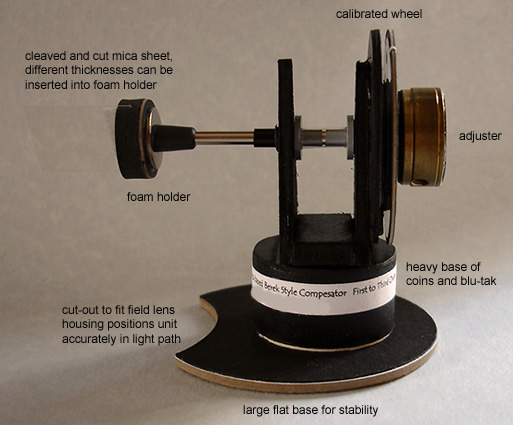

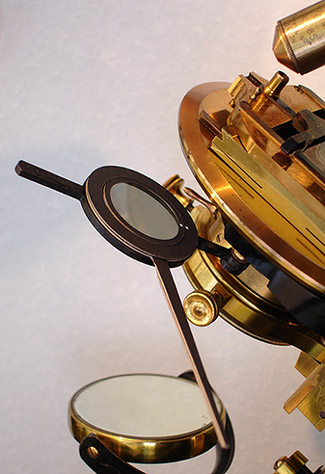

Fig 1.

Original compensator - a heavy base design for a

Zeiss microscope with built in illumination,

flat base and horizontal stage.

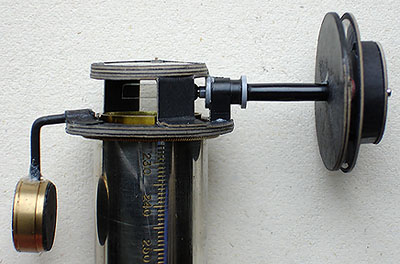

Fig 2.

Top view of the original compensator.

The idea of this article is not to give detailed instructions,

measurements and

materials of the unit I have built, but the concept which can be adapted

to whatever

microscope you might like to use and materials you have to hand

including any of your own improvements

you wish to make. Ideally you first choose a favourite low power

objective in this case my Swift 1" achromat and set the microscope up

for optimum contrast with the condenser iris and then fix the unit in

position, you could then use other objectives but you will need to know

where you normally set your condenser for the higher or lower power

objective since you do not want to be continually removing the

compensator from the tube to allow setting of the condenser. It is

worth

making a prototype for your own microscope to find whether it is

feasible for your stand, the main point being sufficient eye relief.

However I find both the 5x and 8x eyepieces for my Swift

stand work well even though the uppermost part of the compensator

stands several mm away from the eyepiece although

your eye must be held very close to the compensator.

Why use a variable compensator?

The first thing is, I and

am sure many others, would like to emulate to a certain extent those

accessories normally reserved for the very few and fortunate folk in

laboratories who can use extremely expensive Berek and other

variable compensators. Unlike fixed compensators such as the 1/4 or

full wave plate

the variable compensator can provide a range of interference colours

which can be useful in familiarizing oneself with the Michel-Levy chart

and see for real the colours that are normally reserved for books and

which are

nothing short of amusing in the variations of print quality. I have

several books with the Michel-Levy [birefringence] charts and they

differ enormously; so

much so it is difficult to know which to trust. You can also do simple

experiments determining the birefringence of a mineral in thin section

by canceling out the colour and measuring the figure on the

compensator, this is detailed in my last article.

Prototype for a miniature

compensator.

Fig 3.

The prototype was made from card cut by a compass cutter

with additional

low slung counterweight to improve stability, left to right is approx

7.5cm.

To allow the idea to come to fruition

I used a working prototype which could be modified to include

improvements as I used it in practice and found any shortcomings. The

main problem for the prototype is the likelihood of the unit falling

off the eyepiece

tube and with the unit only weighing 10 grams but with the

measuring disk to one side, the centre of gravity tends to pull it off

the tube, so I included a small brass counterweight to compensate which

worked well. As with my previous design I used a thin cleaved piece of

mica which rotates about its axis to provide different amounts of

compensation introducing the various interference colours from lower

first to mid order second in distinct bands, the colour bands are much

more clearly defined than my first design probably because the mica is

so close to the eye. The various parts are held together by glue stick

and rubber

solution allowing them to be dismantled to a certain extent and

re-assembled to include new

ideas. Some of the parts are from an old video recorder including the

steel spindle running from the mica plate to the adjustment disk and

the grey plastic bearings are from transistor insulators. A possible

source of mechanical parts for projects like this are discarded 3 1/2"

and 5 1/4" floppy drives and CD drives from desktop computers where you

will find a number of small parts from the mechanism which may work.

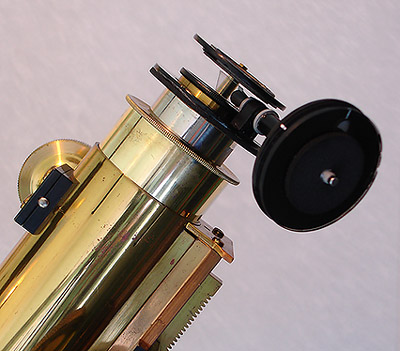

Fig 4.

A side shot showing how it fits to the eyepiece tube, eyepiece removed.

In Fig 4. you can see how the

prototype is built up from layers of thin card glued together to

increase strength and

stability. The lower disk fitting around the eyepiece tube is a

precision fit to accurately centre the unit on the microscope. The

cheap polarizing disk forming the microscope analyzer [available from

Knight Optical UK] is temporarily glued into place on the upper ring

with spots of rubber solution easily removed when

necessary. The picture gives an idea of the close tolerances between

the various parts and eyepiece tube. The length of plastic tube to the

rotating

measuring disk is calculated to allow sufficient clearance not to

interfere with the face when in close proximity to the unit. A delicate

touch is required when adjusting the unit so as not to displace it off the

microscope. Incidentally the inverted 'L' shape black plastic holding

the grey bearings is a small section cut from the cable retainer

found in a very old household 13 amp plug [these normally have the two

screws passing through it holding the cable into the body of the plug

but sadly the more modern ones are flimsy affairs]. However in the last

year or two plugs in the UK have become molded and no useful parts, it

worked so well it

was used in the final version.

The improved and final

design.

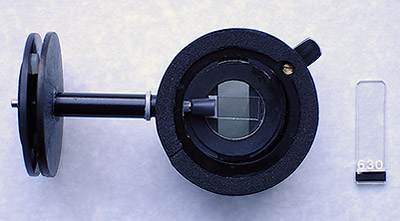

Fig 5.

View shows calibration marker on lower ring for aligning

unit to eyepiece

tube and additional 630nm compensator in situ. Top ring

maybe swung-out.

For stability the final design main

components are made from perspex which gives the unit much longer life

and

more stable operation than card unfortunately I have no easy way of

cutting accurate larger circles in perspex so I have to do it by

drilling a number of small holes neatly around the required hole size

snapping

it out and finishing by hand as shown at the end of the article

in Fig 18. The

compensator shares a number of

concepts from my previous design including the measurement scale built

around a small disc shown on the left hand side of Fig 5. A very rigid

plastic tube holds this fixed disk in position with its calibrations

allowing the steel spindle to rotate within when moving the free disk

far

left. The analyzer

is fixed uppermost on the unit whilst a sufficiently wide window

accepts the additional

compensator below it without interfering with the field of view looking

at the

subject. End stops on the calibration disk prevent the mica rotating

more than 90 degrees.

Once the perspex has been cut and filed completely round I applied a

thin coat of

black gloss spray paint to give a nice finish and allows the various

calibrating markers shown in white Letraset decals to stand out. A thin

slice of Knight Optical full wave compensator cut to the right

dimensions and orientation allows an addition to the variable mica

plate

plate to allow measurements up to third order

increasing its versatility over my previous unit.

Fig 6.

Bottom view of unit showing foam base and additional 630nm compensator.

Fig 6. shows the 2

mm thick

high density foam which grips the eyepiece tube

flange firmly on my stand but allows slight rotation to allow the unit

to be aligned accurately in conjunction with the microscope polarizer

to give optimum

extinction, this could also be achieved by rotating the eyepiece tube

with the unit in position if

free movement is available on the stand. The mica plate is held by a

small rubber cup with a sharp knife cut to accept the plate and it is

not

held in place by

any adhesive. The additional full wave plate which is a slide fit is

held

by card rings cut in the correct size and orientation as shown above.

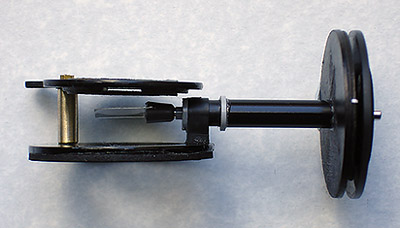

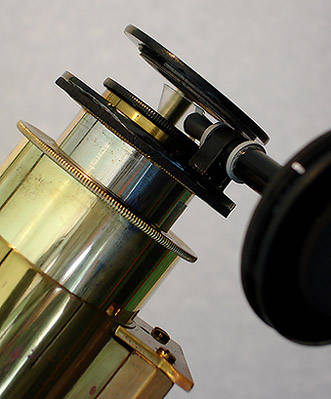

Fig 7.

Side view showing mica plate and slot for additional

compensator plate above.

Fig 7. shows the sturdy

brass

pillar holding the two perspex rings apart this has a long brass screw

running

through it fixing the two together however a nylon washer allows free

movement

of the upper ring holding the analyzer and additional compensator to be

swung out of position and together with the mica plate in its vertical

position allows normal viewing of subjects. This picture also shows

clearly the additional compensator slot in the top ring in this case

end on.

Fig 8.

Home made polarizer mount with long arm facilitates optimum

alignment in E-W direction with a known source

shown in Fig 9.

Fig 8. shows the matching

Knight Optical polarizer

swung out of its normal position on a mounting ring with a long arm

allowing rotation in the closed position beneath the condenser to

provide optimum extinction with a known polarizing source such as the

Zeiss Jena eyepiece unit set up N-S shown in Fig 9. Once we know that we

have the polarizer accurately set for E-W and analyzer N-S measurements

made with the compensator set for 45 degrees to the polarizer following

standard petrological techniques. I go through this procedure every

time the compensator has been off the microscope to provide optimum

results only taking a few

seconds to check. The home made mount shown above allows quick removal

of the centre polarizer disk to take dark-field stops, rotatable colour

Rheinberg rings stackable with the polarizer if desired to give

different hues and plain green and blue acetates.

Fig 9.

A known source such as this Zeiss Jena analyzer is used to

accurately

orientate the polarizer in Fig

8

Fig 10.

Overview of the compensator fitted to an old Swift stand,

the design

relies on accurate friction fitting of the unit to the eyepiece tube.

Fig 10. shows the home made

compensator fitted to the microscope in its normal operating position,

the eyepiece tube has been purposely pulled out by about 10mm to show

the unit is stable without resting on the flange of the main brass gear

tube

assembly below but the design was based on the tube being normally

closed. One important point which is not clear in Fig 10. is that the hole

drilled in the base ring of the compensator must allow the eyepiece to

pass through, the compensator is gripping a small knurled flange about

2mm below the eyepiece as seen in Fig 9. which is part of the

design of my particular microscope. This is why it is important to look

at your own microscope for some time make a prototype and adapt the

compensator to fit your own needs. It was common for Victorian and

Edwardian brass microscopes to have these larger flanges just below the

eyepiece which is a convenient place for the unit to rest and grip.

Fig 11.

Perspex adjustment ring and window, retardation calibrated in

nm.

A nice shot of the compensator is

shown in Fig 11. here

the analyzer can be clearly seen on the uppermost perspex disk held in

position by a friction fit card ring. The rotating and measuring disk

looks unnaturally large here being a macro shot and distorted

perspective. The perspex rotating disk is accurately drilled to be a

friction fit on the steel spindle but due to being only

1.5mm thick requires a stabilizing dense foam disk which also doubles

as a comfortable and convenient point to rotate the disk.

Fig 12.

Close-up of the mica plate showing the close tolerances

requiring accurate cutting and measuring of parts.

Fig 12. zooms in

on the mica showing the very close working distances between the

rotating mica and

the top of the eyepiece together with the lower face of the card

holding the additional compensator.

The 'L' shaped black plastic bearing holder carefully sawn from the

cable retainer mentioned earlier

can be seen together with the two grey bearings made from transistor

insulators the two together giving a smooth damped feel to the rotation

of the mica.

Results.

I must stress that my compensator is specifically made for visual

observation [your own could be more rigid and improved] since the

structure is not strong enough to hold the weight of a digital camera

also the camera would need a zoom of 4x with my eyepieces to remove

vignetting but for demonstration purposes I have taken some sections

from the standard circular field of view using a hand held digital

camera sitting lightly on the unit. This gives an idea of the colour

range obtainable, Figs

14-15-16.

were taken without the additional 630nm fixed compensator. Fig 17. shows a limited

view with the 630nm plate in position extending the compensating range

to third order. The minimum compensation of my compensator is around

250nm [1st order grey-white on the chart] but this could be adjusted

depending on the properties of the mica sample but with the mica in the

vertical position most of the original subject can be seen without the

effect of the compensator.

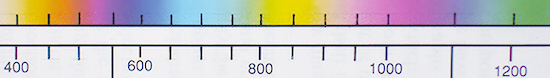

Fig 13.

Typical section from a printed birefringence chart for reference below

with some of my own rulings.

Fig 14.

With the mica almost horizontal in the light path the lower order

interference colours can be seen.

Crop from the camera set at 2.4x optical zoom, now we will increase the

angle of mica in Fig 15.

Fig 15.

A very distinct set of colour bands is seen from 1st order

yellow 400nm to 2nd order blue 700nm.

Colours depend on the angle of mica in the light path, a crop

from the camera 2.4x optical zoom.

Fig 16.

Zooming into the colours, 1st order deep orange 500nm to 2nd

order blue 750nm.

Close crop with the camera set to 3x optical zoom showing smoother

gradations.

Fig 17.

Using these colours together with a Michel-Levy chart we can do

experiments with thin sections...

Crop from camera 3x optical zoom, +630nm compensator giving 3rd

order 1130nm to 1300nm.

And finally, some of the

tools and parts.

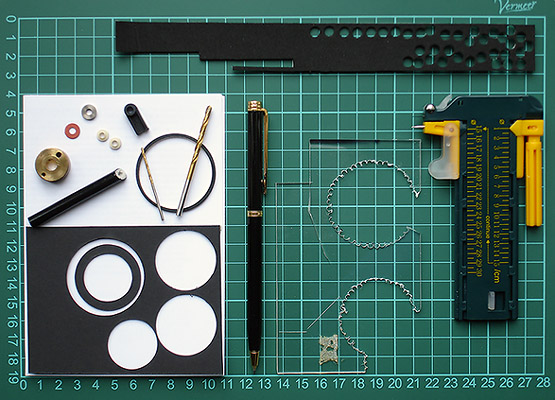

Fig 18.

Some typical tools and materials that went into building the miniature

variable compensators.

Plastic tubing, circular cutter, perspex, small drills, parts from an

old video recorder, card and foam etc.

Conclusion.

The

compensator can give older biological microscopes including Edwardian

and

Victorian stands fitted with rotating stages and external light sources

the chance to be used as interesting polarizing microscopes with a hint

of the exotica

normally reserved for the modern dedicated polarizing stands

costing more often than not several thousands of pounds. Small parts

like the transistor insulators [the same design also used for 1 amp and

3 amp low voltage DC regulators] are most likely still available from

large electronic component suppliers online like RS, Farnell, CPC or

Maplin in the UK. However with a little ingenuity from your own

'bits-n-bobs' around the house no surplus electronic parts are needed

in the main construction such as the bearings for the spindle just a

source of material suitable for the compensator plate.

Comments to the

author,

Ian

Walker,

are welcomed.

Reference.

A

variable compensator for microscopes [My original and larger design

written for Micscape earlier in 2006, this includes more detail on mica

and experiments with thin rock sections].

Related

articles

Notes on mica in the light train of a

transmitted polarized

microscope

- Gordon Couger provides some valuable

notes on sourcing and cleaving mica for homemade compensators in his article

in the November 2006 issue.