A Variable Compensator for Polarized Microscopes.

Simple experiments with cleaved mica.

By Ian Walker. UK.

Introduction.

Amongst my interests in microscopy are photography of subjects in polarized light and the study of thin rock sections where I enjoy carrying out simple experiments investigating mineral type etc. The idea came when looking through a 1970's book by Paul F. Kerr 'Optical Mineralogy', in the section about polarizing microscopes Kerr shows a picture of an old Leitz Berek compensator using calcite, Max Berek developed this style of compensator in 1913 as a variable waveplate and normally these expensive but accurate compensators are placed between the objective and viewing head in a special slot designed for the insertion of retardation plates. They measure the interference colour by the observer adjusting the compensator control which in turn rotates a piece of calcite specially cut for the required properties, this neutralises the interference colour of the crystal or fibre under test to dark grey or black when the retardation of subject and compensator are the same but in opposition, the reading from the vernier [angle of calcite] is then translated to a retardation value in nanometres [nm]. A quick check on the Internet and it seems Olympus and Zeiss [and probably others] are still making Berek compensators and if you wish to read more I suggest the Molecular Expressions link at the end of the article. These type of compensators are thousands of pounds, the Zeiss shop [UK] lists two types both over £3400 and therefore way out of most amateurs reach and that's providing you've already spent a large sum of money on their matching microscope. The modern Berek compensator still uses calcite [an alternative being magnesium fluoride used for the narrower compensation range] and can be bought in 0-5 lambda all the way up to 0-30 lambda whilst still attaining good accuracy of measurement due to the 'slow motion' mechanism and vernier resolution. My compensator works in a similar manner as the original Berek design using mica rather than calcite, the outcome adhering to the same principle albeit over a narrower range of retardation, the fun was to try and emulate in ultra-simple form a very expensive microscopy accessory.

Aims.

1. Obtain a continuous range of interference colours from 1st and 2nd orders, or by the use of thicker section extend the range to higher orders.

2. Generate colour backdrops for polarized light photography.

3. Easy and cheap to build from available materials.

4. Allow simple experiments similar to using a professional Berek compensator in the help of diagnosing interference colours from minerals in thin section or transparent materials placed on the stage.

Initial ideas and selection of microscope.

My first experiments involved nothing more complicated than that shown in Fig 4. A chopped off cotton bud with a little blue-tak ball fixes the mica sheet allowing tilting or rotating of the mica in the light path between my polarizer sitting on the field diaphragm [Fig 7.] and the condenser. Normally these compensators would sit above the objective but this leaves very little in the way of experimentation due to the small slots for retardation plates on most polarizing scopes [or none at all on biological scopes modified for polarizing use] and the quality of the material itself is of lesser importance not being directly after your favourite objective, plastic retardation plates or poor quality mica can deteriorate the image if placed above the objective [in the retardation slot if fitted], it certainly does on my microscope.

Below the condenser gives us a lot more room to manoeuvre with home made accessories especially with larger units. A design like this suits most microscopes with built in illumination with some flat area at the base so you can rest it there, less easy would be microscopes with a limb and stage at an angle using a mirror and external lamp as an illuminating source since there is no easy method of fixing it in position. This is my design but you can make any variation you please depending on materials to hand. As you can see from Fig 1. it is of novel construction looking not unlike a very early 'prototype' of the 1960 film version of H. G. Wells 'The Time Machine' starring Rod Taylor, more on that later. Since I have a background in electronics I have mica to hand from old insulators used in mounting certain types of transistors and voltage regulators to aluminium heatsinks; these are very useful for tests being already cut to small convenient rectangular shapes [they use plastic materials now] but after experimentation I did not use these but used a piece of mica cleaved from a large insulator found on a pavement from a street lamp that had been broken. Cleaving small pieces of sheet mica is quite straightforward due to its characteristic perfect cleavage and cutting the cleaved section with a very sharp blade to produce a rectangular shape is easy but I had to experiment a little with thicknesses suitable for providing the correct retardation range I was looking for.

Cleaving the mica.

You must get the orientation of the mica correct for the compensator to work, the best method is to try a small practice piece from the parent mica sheet and offer the mica up to the light path using the simple device shown in Fig 4. try the sample piece of mica in various orientations until you are happy that you are getting the desired effect then use this to determine the 'cut' of the final piece. I have cut the orientation of my mica so the compensator works best offered up to the light path at 45 degrees relative to the polarizer-analyzer, the standard.

As always with materials like mica some common sense has to be applied with having a suitable area to work and receptacle for collecting unwanted fragments, try avoid handling mica directly with the fingers especially if you have cuts or abrasions, if you are afraid of inhaling mica dust, wear a quality disposable face mask but if you cleave accurately and use a very sharp knife it is surprising how little dust or fragments will be generated provided the parent material is of good quality.

Other materials.

I tested the plastic Knight Optical retardation material, the 140nm didn't work in any orientation in the light path or tilted other than its native light grey interference colour but the 560nm did work albeit duller colours than my cleaved mica requiring higher light output from the lamp and seeming to produce the colour spectrum from blue [see Fig 17.] back towards 1st order colours in the reverse order to mine as the plastic was tilted!

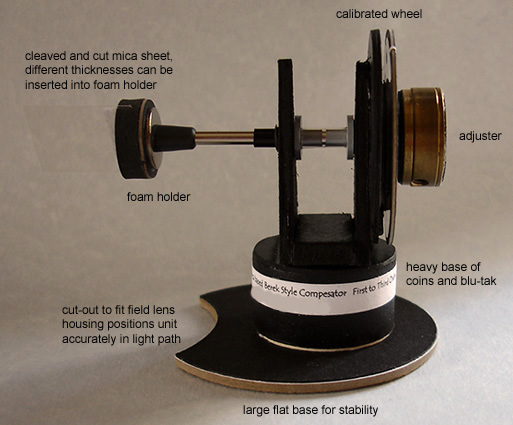

Building the variable compensator.

You can build any design you like as long as the mica or your preferred material can be rotated with some degree of accuracy. The round foam holder for the mica plate is a foot from an old aluminium instrument box cut to accept the plate[s], the steel rod and brass adjuster came from old VCR mechanics, the 'bearings' are insulators from transistor mounting kits, the base is filled with a sandwich of coins and Blu-Tak and then wrapped in black card which in turn is stuck to a larger card base for stability and with a few more washers etc that's about it. Total cost about £0.08 for the coins! It does help to save bits and pieces as gear comes to the end of its life. I keep electronic circuit boards and mechanical components from dismantled cassette decks, video recorders etc going back many years, dismantling the useful parts from them when they have come to the end of their working life and it is surprising how many interesting items you could salvage from cassette decks like my Technics which gave good service for over 20 years. However, less so now in the 'throw away plastic' electronics revolution due to lack of decent parts and a significant reduction in build quality.

Fig 1.

Component parts of a simple variable mica compensator for polarizing microscopes.

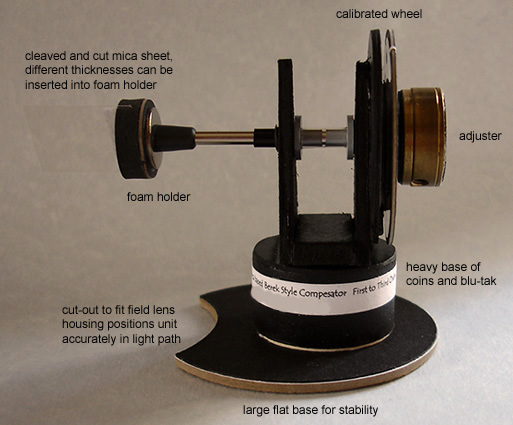

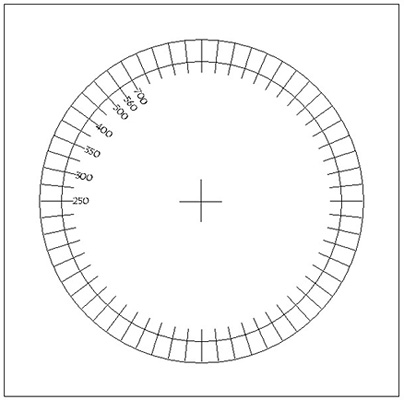

Figs 2, 3.

Top view and close-up of calibrated retardation scale [nm] seen through a small 'window'.

Fig 4.

Prototype nothing more than a cut-off cotton bud with mica sheet under test, hand rotated or tilted in the light path. I still use this for testing new materials.

How does it work?

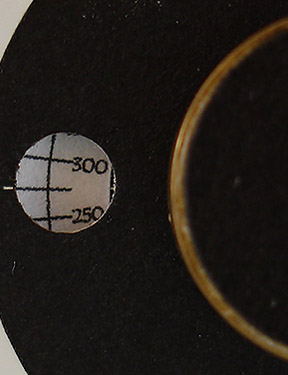

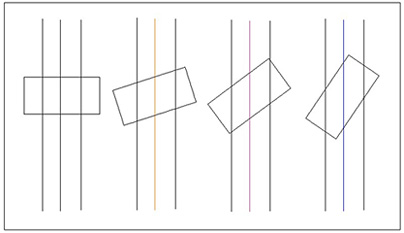

Fig 5.

The above schematic and following paragraph is my understanding of how the compensator works but it is possible there is a more complex issue regarding orientation of the crystal structure within the mica when rotated so I will remain corrected!

An extremely simplified and exaggerated view looking into the end of the cleaved mica, consider the central ray of light only. In the horizontal position the mica offers up to the ray of light passing through the actual thickness of the cleaved section but as the mica is tilted this thickness effectively increases very slightly getting greater as the angle increases so the mica is becoming 'thicker' and 'thicker' as far as the ray of light is concerned generating higher and higher order interference colours. A typical quartz wedge approximates to 'zero' for 1st order to only 0.15mm thickness for about 3 orders of retardation so it is not surprising that tilting mica cleaved to the correct thickness can emulate the wedge but I think my unit has an advantage over the wedge being able to cleave the mica to the thickness most desirable to the range of compensation you wish which in my case is between 150nm to about 850nm. A standard quartz wedge might show five orders of interference colours making the colour bands under view much more compressed for the same magnification. I also cleaved another section of mica which can be easily inserted into the foam holder shown in Fig 1. to obtain higher order colours but with compressed colour bands at the lower orders, this is a useful diagnostic looking at minerals in thin rock sections with higher interference colours like magnesium rich olivine with a retardation in the order of 1050nm for a standard thin section of 0.03mm.

Fig 6.

A very basic Turbocad printout with pre-calibrated retardation readings in nanometres [nm] before being cut-out by a circular cutter and applied to the round cardboard disk behind the rotating wheel, I only use a quadrant so calibrations are within a 90 degree rotation, with the accuracy of colour above about 750nm more difficult to achieve consistently I only calibrated from 250nm [light grey] to 700nm [blue] covering most of the 1st and 2nd order colours on a colour interference chart. Stops on the rotating wheel prevent the mica plate going just beyond the horizontal and vertical positions. The 250nm marker is rotated at a slight angle to the horizontal since my mica starts with retardation of about 150nm. The calibration markers were my best estimate using interference charts and cross-referencing with known value retardation plates.

Fig 7.

One position of the unit aligned at 45 degrees to the polarizer-analyzer, notice the very clean cut to the edges of the mica to obtain good results and the angle of mica which for illustration purposes is also set at about 45 degrees to the light path in this picture. The polarizer on the field diaphragm can be continuously rotated either quickly by moving the whole Perspex mount or slowly by turning the Nikon mount and is useful for plane polarised light experiments with thin rock sections, it is based on a Nikon 28mm circular polarizing filter with the original polarizer removed and replaced with a Knight Optical linear polarizer of the same diameter.

Fig 8.

Another position of the compensator 90 degrees from its previous position but still 45 degrees to the polarizer-analyzer, this is where the part circular cut-out shown clearly in the top view of Fig 2. comes in useful as the unit can be rotated smoothly into either of two positions for convenience whilst being kept in good alignment within the light path. At this position you can see how small the piece of mica can be and still offer good coverage even using a 4x objective. Typical older mica insulators for transistors and voltage regulators are of very similar size but are susceptible to damage and tend to be ragged at the edges causing colour anomalies when the mica is rotated.

I have used some terms common to mineralogy and thin rock section study under the microscope in the following text so I will list a few explanations below for those not familiar; unfortunately more often than not as you try to explain one term another one usually appears so for those who wish to skip these definitions carry onto the interference colour sequence below.

petrographic thin section, the study of rocks ground to transparency, normally to a thickness of 0.03mm.

cleavage, many minerals cleave or break along certain planes, the positions of which are controlled by the atomic structure of the minerals. Between cleavage planes the atomic bonding is weak compared to within the planes. The presence or absence of cleavage and the angles between cleavages if more than one cleavage is present, may be of diagnostic value.

birefringence, the quantative measure of double refraction, defined as the difference between the maximum and minimum refractive index [R.I.] of a mineral. Birefringence can be measured with some accuracy using the birefringence chart [interference colour chart], assuming a common thickness for rock sections of 0.03mm.

isotropic and anisotropic, minerals having one R.I. are made up of a very regular arrangement of atoms so that light passes through the crystal with the same velocity irrespective of the direction in which it travels, such minerals show no double refraction and appear black when viewed with cross-polars, all other minerals are anisotropic going into extinction 4X in a 360 degree turn of the rotating stage with crossed-polar's.

absorption colour, the colour of a mineral when viewed in plane polarised light, [polarizer only in light path].

pleochroism, the change of colour of mineral in plane polarised light when the mineral is rotated with respect to the plane of polarisation, a very useful diagnostic property for some minerals.

extinction position, the position of which a particular grain of crystal becomes black under crossed-polar's, this extinction occurs every 90 degrees of rotation of the stage.

extinction angle, the angle between the extinction position and some well defined direction in a crystal, [eg: cleavage] and is usually less than 45 degrees, this may be of diagnostic value.

twinning and zoning of crystals of the same mineral in which the orientations of the two or more parts have a simple relationship to each other. Zoning is the term used to describe changes in crystal between its core and outer rim.

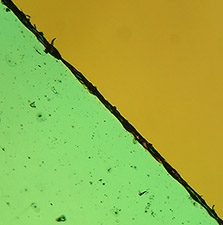

Some interference colours in sequence from 1st to 2nd order.

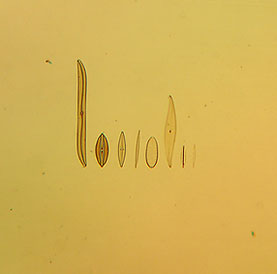

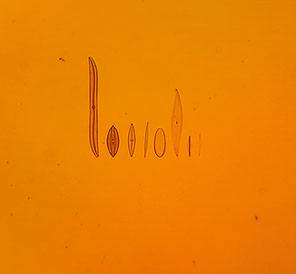

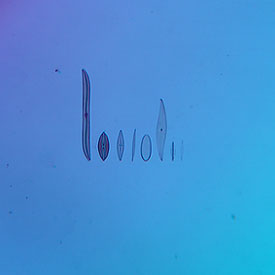

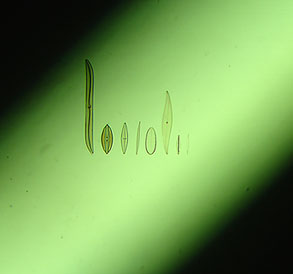

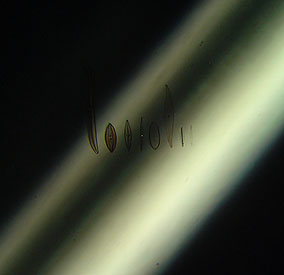

Just a small collection from the spectrum of colours that you can expect from a mica plate like this. My Sony P200 digital camera handheld at the eyepiece has done an acceptable job of portraying the colours seen and because the camera needed something to focus otherwise the shutter wouldn't fire I selected a none polar active subject [in this case an eight form diatom test plate by Klaus Kemp]. As you reach the narrower bands of 1st order colours part of the sequence can be seen spread across the field of view using a low power objective, these images from a 6.3x objective show only one colour because of the greater magnification and some cropping from the original images.

Figs 9, 10, 11.

1st order colours, cream-yellow, orange and purple, Fig 11. is a fairly good representative colour of the common 'tint plate'.

Figs 12, 13, 14.

2nd order colours, blue, light blue-green and green.

As rotation of mica increases the colours go up the colour spectrum, the effective width of the mica diminishes and the band of colour narrows.

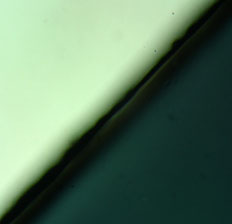

Figs 15, 16.

As we reach near vertical positions in Fig 15. and Fig 16. the colour is becoming amorphous and unreliable but my alternative thicker mica section provides higher order interference colours at a reduced angle offering better accuracy. In the vertical 'rest' position with thin rock sections the mica becomes virtually invisible if accurately adjusted so I leave it in the light path.

Simple compensator experiments with cellophane and commercial retardation plates.

Fig 17.

A modestly priced plastic retarder from Knight Optical with a marked value of 560 +/-80nm is placed on the rotating stage and focused instead of a prepared slide, it is filling only the lower right hand section in Fig 17. appearing dark grey, this is because the colour is being removed by my compensator set to the same retardation value as the Knight Optical retarder which in this case can be seen as light blue in the top half of the picture. It is sufficient to say in this experiment there will be two positions of maximum interference colour in the full 360 degrees rotation of the retarder on the stage where the effect of the compensator will add and two positions at 90 degrees to those positions where they will subtract.

The 2nd order colour produced by the Knight Optical retarder [650nm estimated from a colour interference chart] is at maximum contrast when 45 degrees from any one of its four extinction points and in the lower half I have adjusted the compensator as you would a commercial Berek compensator and found where it cancels out the colour to arrive at dark grey, I then read off the value and it is also around the 630 nm mark so the retarder is probably just on the borderline of its specified value. If I rotate the plastic retarder 90 degrees on the stage the compensator retardation will add creating a whole series of colours from 2nd to 3rd order in sequence as it is moved from horizontal to vertical.

Figs 18, 19, 20.

Fig 18. Shows a Knight Optical plastic retarder placed on the stage marked with a value of 140 +- 20nm behaving like a 1st order 1/4 wave plate, it only fills the lower right half as in Fig 17, note the camera exposure has been upset by the high contrast and should appear darker than shown. This time my mica compensator is in its vertical 'rest' position shown by a 'ghost image' running perpendicular to the edge of the plastic retarder running from the top left corner, most of the upper half shows the dark background produced by the crossed-polar's. Rotating the mica compensator to horizontal as shown in Fig 19. and its just about compensating the interference colour produced by the Knight Optical retarder from a light grey to dark grey suggesting my compensator minimum value is starting around 150nm. In Fig 20. I have purposely over compensated to show how easy it is to set the mica to the correct position to match the subject under analysis. If I rotate the Knight Optical retarder on the stage by 90 degrees [not shown] the two colours will add to around 300nm, an area of confusion where it is difficult to accurately assess the colour.

Cellophane tests.

Figs 20, 21.

Fig 20. shows a piece of cellophane set up as in Fig 17, this time before using the compensator I observed the interference colour produced by the cellophane resting on the stage and I was not sure whether it was producing a 1st order or 2nd order 'yellow' since they can be very similar but now I have adjusted the compensator to cancel the colour produced by the cellophane I can read off my compensator and found that it is indeed a 1st order yellow around 400nm retardation. Turning the stage 90 degrees and now the effect of the compensator is adding to the colour produced by the cellophane 400+400nm=800nm a pale green as shown in Fig 21. The interference colour produced by materials like cellophane from the wrapper of a birthday card tend to be more vague compared to the much stronger colour produced by a well cleaved piece of mica.

I have three books with interference colour charts and they are all different in the way the colour bands and spread are portrayed partly due to age and different printing methods so there is a degree of latitude in reading these charts and indeed at the lower end of the scale in the dark to light grey of 1st order quite a margin of error is possible. Also the quality of extinction of the crossed-polar's and colour temperature of the illuminating source of the microscope can all have an influence on the subjective appraisal of these colours.

Some simple experiments with thin rock sections.

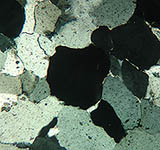

Figs 22, 23, 24 ,25.

Fig 22. I have selected Slide A. from the Open University OU 260 thin rock sections which consists of quartzite from Skye, Scotland and found an extinction point of the central crystal recording the reading on the rotating stage.

Fig 23. Rotation of the stage 45 degrees to arrive at one of the maximum interference colour positions.

Fig 24. Introducing my compensator I find that I cannot reduce the interference colour of the quartz to black [the effect of the interference colours are adding because of the relative orientations of the compensator and crystal] so I set my compensator to minimum setting of 150nm and check the resulting colour which is approximately 260nm [from lists of minerals printed on the interference chart] +150nm [minimum setting on the compensator] producing around 410nm, a 1st order yellow which seems correct when checked against the interference chart, note the similarity in hue compared to my cellophane experiments which had roughly the same retardation value.

Fig 25. Knowing the position of where addition of the two interference colours occurs I rotate the crystal 90 degrees on the rotating stage, the two colours should now cancel creating a dark grey or black crystal [devoid of colour] when I set the compensator to the same retardation value as quartz, this works successfully and I read off the value as 290nm on my compensator... not a bad result considering the maximum retardation value of quartz printed on one of my interference charts is 260nm and their will be some variation on this figure depending on sample thickness. Notice in Fig 25. that some of the crystals are producing 1st order colours since their various orientations will be such to add to the compensator to different degrees. Not all the quartz crystals were creating the same maximum interference colours [a range of 1st order grey's to whites] perhaps due to variations of thickness or orientation of certain crystals within the thin section.

Note: In the above images for illustration purposes only my Sony P200 digicam was handheld onto the eyepiece of the microscope so the angle of the camera offered upto the eyepiece was not the same in each case, the orientation of the central crystal might not appear to be rotating exactly as expected.

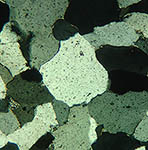

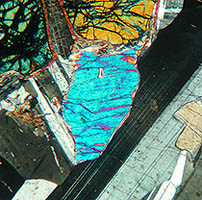

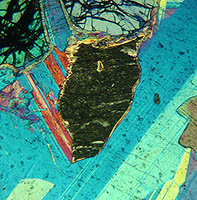

Figs 26, 27.

Fig 26. I have selected Slide K. from the OU 260 thin rock sections which is gabbro from Huntly, Scotland. The essential constituents of gabbro are clinopyroxene and plagioclase feldspar according to my book 'Colour Atlas Of Rocks & Minerals In Thin Section' by MacKezie and Adams. However, olivine is also present in this sample shown at the top centre with the deep lines of irregular cleavage and interference colour of orange due to its present orientation. The twinning of the plagioclase can be clearly seen in the dark-light grey of the crystal running up the right hand half of the image but it is the central crystal of what I believe to be clinopyroxene which I have selected for interest. I have adjusted the crystal orientation for its maximum interference colour which in this case is predominantly light blue whilst in plane polarised light the crystal appears nearly colourless without pleochroism. Augite is one of the clinopyroxene's commonly found in gabbro but my Colour Atlas suggests a birefringence of 0.035 giving an interference colour right at the top of 2nd order pink but Paul F. Kerr in 'Optical Mineralogy' suggests a much lower birefringence of augite between 0.021-0.025 giving a predominantly 2nd order blue just as it is in my sample. It is possible [from my limited knowledge] that the ratio of the chemicals that make up the mineral augite can change significantly depending on the parent rock location creating these differences in maximum birefringence suggested by these text books?

Fig 27. I have rotated my compensator to cancel the interference colour of the crystal and I have read the retardation figure at 700nm equivalent to a birefringence of 0.023 so either the thin section is not to the standard 0.030 mm thickness but thinner, creating a lower order colour, or the data in my Colour Atlas book is confusing me, the plagioclase is providing the 1st order colours expected suggesting the preparation thickness is OK. Alternatively my diagnosis is completely wrong and it isn't a clinopyroxene crystal, all the other crystals of the same type were showing the same maximum interference colour so if it is an augite crystal my reading seems to agree very well with Kerr being right in the middle of the expected range of birefringence.

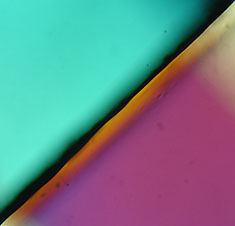

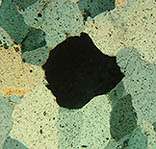

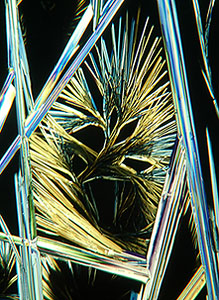

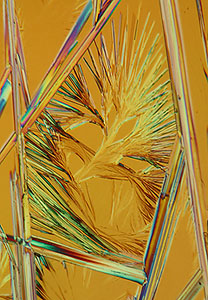

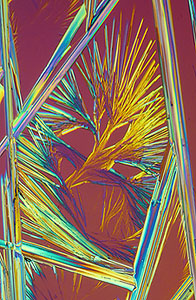

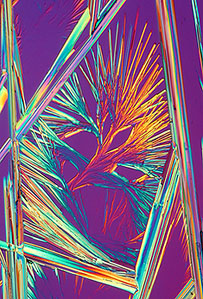

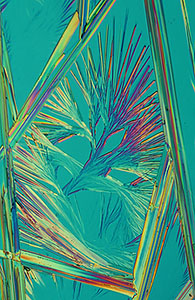

Crystal photography, same slide different colours.

In the images below I have used a 10x objective, firstly with crossed-polar's only then introducing a selection of interference colours achievable from the mica compensator. I chose a complex slide of crystals [sodium platino-cyanide] mounted by an unknown mounter showing how the colours in the crystal structure change whilst leaving plenty of space to show how the background colours also change. Unfortunately the camera hasn't really done justice to the vibrant colours I saw down the microscope.

Crossed-polar's only moving to a 1st order colour of about 450nm retardation.

Going towards 500nm retardation.

Moving to around 550nm on the left and 750nm retardation on the right.

Conclusion.

With a little patience and simple materials we can learn a lot about the principles of microscope accessories like the Berek compensator and how it works in relation to the rest of the system, also how it interacts with crystals and minerals in thin section. Most of us can never afford a modern polarizing microscope by Olympus, Leica or Zeiss let alone their dedicated polarizing accessories [see below] but we can certainly appreciate some of the ideas behind units like the Berek compensator and have a lot of fun with an outlay of just a few pence. If you don't like the results you can always put the nuts and washers back in your scraps box and the £0.08 in the microscope 'bank' ready for the next project. Reading about retardation plates, quartz wedges, plane-polarized light, pleochroism, extinction angles and compensators the principles are not always clear until you've had a go... built and experimented... it can make reading those big lofty text books on mineralogy and principles of polarizing microscopy somewhat more enjoyable.

See also my brother's article this month adding a home made 'polarizing monocular tube' to a LOMO Biolam to do simple experiments with retardation plates and diagnostics on thin sections.

Out of interest I logged onto the Zeiss online shop where you can buy microscopes direct from Zeiss UK; the cheapest stand that provides a polarizing option including rotating stage, polarizer/analyzer/auxiliary slots is the Axioskop 40, all prices include 17.5% VAT, prices are correct as writing the article in April 2006.

Basic stand £5700 including three CP achromat's none of which are strain free: 5x/0.12 £45, 10x/0.25 £93 and 40x/0.65 £181.

Upgrade to 5x/0.13, 10x/0.30 and 40x/0.85 strain free plan-neofluars add £5347.

Rotating polarizer/analyzer upgrade from basic plug-in units add £2773.

0-5 lambda Berek style compensator add £3409 and finally 0-30 lambda Berek style compensator add £3595.

So if you would like their stand with 3 plan-neofluars upgrading to a rotating polarizer/analyzer and fancy the 0-5 lambda Berek compensator they will sell you one just short of £17230!

A strange story.

On April 1st [and only for those who know the significance of the date] I was doing observations down the microscope when a series of quickening flashes came through my eyepieces as my compensator seemed to have started revolving by itself breaking its endstops with a flurry of cardboard. The light overhead started to dim and the slides in my wooden box started to chatter jumping about in their holders when a strange glow came about the room. Where my compensator stood there was now an orb of light getting brighter and brighter when with a sudden melancholic sound my compensator vanished, I assume now traveling in the fourth dimension to some unknown time : )

References.

Molecular Expressions. Berek compensators.

Previous Micscape article. Open University OU260 thin rock sections.

Knight Optical UK. Supplier of retardation plates, filter and polarization materials etc.

Comments to the author, Ian Walker, are welcomed.

Published in the April 2006 edition of Micscape.

Please report any Web problems or offer general comments to the Micscape Editor .

Micscape is the on-line monthly magazine of the Microscopy UK web site at Microscopy-UK

© Onview.net Ltd, Microscopy-UK, and all contributors 1995

onwards. All rights reserved.

Main site is

at www.microscopy-uk.org.uk

with full mirror

at www.microscopy-uk.net