Converting a Swift Microscope to a Hybrid Polarizing Microscope

Michael Reese Much RMS EMS

Bethlehem, Pennsylvania, USA

I found this Swift Collegiate 400 microscope on eBay for $50. Looking at the nosepiece, I thought I might be able to put a beam splitter in the nosepiece and convert it to a metallurgical microscope, but I found the nosepiece was occupied by the tube lens assembly. The scope came with 4x, 10x, and 40x objectives, a 1.2 Abbe condenser and no eyepiece. The grease hadnít frozen up and all of the controls worked perfectly. The nosepiece was loose and wobbled considerably. The lamphouse has an 80B filter built in, so it is daylight balanced for photography.

Cosmetically, it was a mess. I found it to be a well-crafted stand and have seen a number of them offered on eBay at modest prices.

One thing I have learned about working on microscopes is the certainty of a small part or screw coming off during disassembly and bouncing off the workbench and onto the floor. I recall removing the objective turret on an Olympus KHC scope and ball bearings pouring out all over my workbench. My wife has frequently seen me on the floor with a flashlight searching for a miniscule part, and she very kindly gave me a telescoping pickup magnet for my birthday. As an added precaution, I always work in a large photographic developing tray when disassembling equipment so all parts are accounted for.

I then line up plastic tubs and cups to keep parts in. I degrease partsin a gallon paint can of naphtha and also degrease parts too big to go into the can with naphtha and a toothbrush. The first thing I degreased was the mechanical stage. I donít re-lubricate scopes and prefer to use them dry. If you do get a Swift Collegiate 400, the two Allen screws on top of the prism housing connect the prism housing to the nosepiece, so access to the tube lens was very easy with standard metric Allen wrenches. On the front of the frame between the prism housing and nosepiece is an Allen screw to control the drag on rotation of the head or to lock the head in position.

Upon disassembly, it appeared I could modify the scope very simply for cross-polarization by putting a polarizing filter between the turret and the tube lens to serve as a polarizer. A couple of years ago, when I bought an Olympus NFK relay lens on eBay, the seller threw in a few eyepiece reticles, a Lambda plate and two small polarizing filters. When I cracked one of the polarizing filters apart, I found the filter was 20 mm across Ė the exact dimension of the space above the turret.

So I glued the polarizer into the nosepiece with epoxy. There was sufficient clearance between the back of the objectives and the filter.

All that remained to be done was to sand down the nicks and scratches and apply new paint. A tip for those who might decide to work on Swift microscopes of this vintage Ė the lamphouse can be masked for painting with the plastic containers CDs come in. Just make a cut in the case so it will fit over the collar of the lamphouse.

And here is the finished scope:

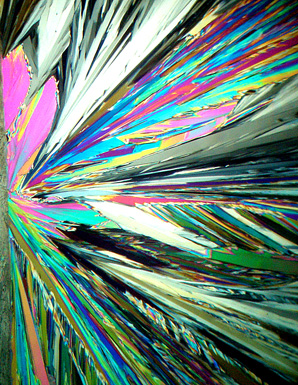

Since the polarizing filter cannot be rotated behind the turret, it is the polarizer. The analyzer is a polarizing filter rotated above the lamp. With this particular polarizing filter setup, I found that a linear polarizer is more effective than a circular polarizer. In the examples below, the left image is the circular polarizer and the right image is the linear polarizer.

All in all, the entire project took a rainy Saturday afternoon, a can of satin black spray paint and some sweat equity. Not too bad for a $50 microscope.

Comments to Michael Reese Much are welcomed.

Microscopy UK Front

Page

Micscape

Magazine

Article

Library

Published in the May 2011 edition of Micscape Magazine.

Please report any Web problems or offer general comments to the Micscape Editor .

Micscape is the on-line monthly magazine of the Microscopy UK website at Microscopy-UK .

© Onview.net Ltd, Microscopy-UK, and all contributors 1995 onwards. All rights reserved. Main site is at www.microscopy-uk.org.uk .