Notes on an 'R & J Beck Ltd' replica Rowland diffraction grating

Includes a comparison with modern gratings.

by David Walker, UK

Old microscope slides which originally merited individual presentation in a velvet lined box usually suggest a subject of particular interest. Examples include micrometer slides, rarer items like the Abbe test plate or finer examples of a slide mounter's work such as Möller's diatom type-slides.

When an item described on eBay as a 'Microscope slide: Transparent replica by Rowland' came up for auction last October in such a case, it attracted my curiosity. From its size in the description it didn't look like a microscope slide but it seemed an interesting antique curio which attracted little bidding and won it for £22.

The closed box with mottled leather finish, measures ca. 63 x 53 x 17 mm.

On arrival, it proved to be a robust glass plate with neatly chamfered edges and corners which at 5 mm thick clearly wasn't one of the microscope test slides with fine rulings which are sometimes seen. The University of Melbourne School of Physics Museum shows an original concave Rowland grating of similar size to the replica mounted in a goniometer, the author's replica example was likely mounted for use in a similar way.

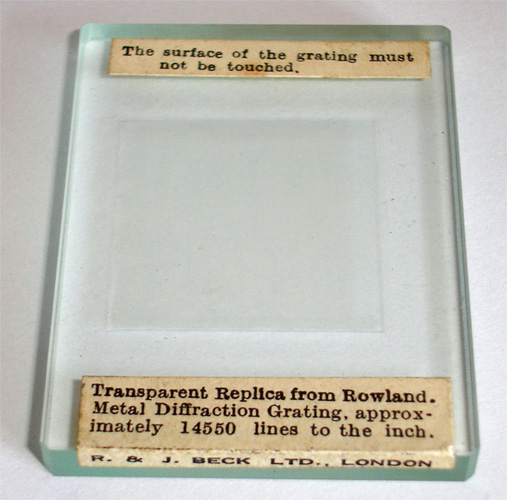

It proved to be an object that prompted a fascinating tour of the literature. The glass plate had two neatly typed labels which seemed to be contemporary with the age of the slide:

Transparent

Replica from Rowland. Metal Diffraction Grating, approx-

imately

14550 lines to the inch.

R. & J. BECK LTD., LONDON

The surface of the grating must not be touched.

'R & J Beck Ltd', the famous makers of microscopes and other optical instruments, requires no introduction but the form of the name label suggests a date after 1894 (1).

The glass plate measures 51 x 38 mm and is 5 mm thick. The grating itself is uncovered and measures 25 mm square.

As the label suggests, the grating is delicate and has some light scuffing over time and some dust captured under mount, but overall is in good condition.

A Google search revealed a wealth of information on Rowland, his work on gratings and this style of replica grating. A selection of resources are linked to below. Henry Augustus Rowland (1848–1901) was a leading figure in 19th century physics in the United States and was the first professor of the subject at the John Hopkins University (see Wikipedia entry). The entry in Chamber's 'Dictionary of Scientists' (2) notes:

“Rowland was the first to succeed in ruling fine gratings on concave speculum metal mirrors to obtain a normal solar spectrum.”

The biography of Rowland on the American Physical Society website includes a photo of him with his ruling engine.

In the above biography it is also noted that he made important contributions in other areas of physics including electricity, magnetism, studies of the mechanical equivalent of heat and a more accurate measurement of the Ohm. The illustrated book 'The Command of Light: Rowland's School of Physics and the Spectrum' by G K Sweetnam (2000) can be viewed in full on Google Books. This is an excellent read and the present author found the attention to detail and engineering tolerances required to make such accurate rulings as well as careful control of temperature, air pressure and vibration particularly interesting.

The history of making replica gratings is equally fascinating. The diffraction gratings made by Rowland using his own ruling engine were of an accuracy not achieved previously but took time to make in numbers and were expensive. Noted workers such as Thomas Thorp (British) in ca. 1898 and later Robert J Wallace (Yerkes Observatory, USA) developed methods of making replicas from masters (3,4,5) typically using celluloid / collodion based films supported on glass; the replica gratings were as effective as originals, thus decreasing their cost and increasing their wider availability and use, including by amateur workers. The papers referenced illustrate that the replicas required great care in developing suitable formulations and techniques to avoid dust, air bubbles and deformation when drying which could affect their use.

The 'NSW' (New South Wales) website shows an example of a Thorp replica diffraction grating. The 'early TECH' shop in UK shows another 'circa 1910' with almost the same lines per inch as the author's, although described as much thicker (20 mm cf the author's 6 mm).

The style of the box, glass supported grating and labelling of the author's example are very similar to the Thorp examples above. A number of R & J Beck's handheld spectroscopes are illustrated online, described as using Thorp's replica gratings e.g. the example on the College of Optometrist's website, so the author's grating may have been made by Thorp for a bench top spectroscope. The author's example bought for £22 possibly reflects its indefinite attribution, the 'earlyTECH' example labelled by Thorp was sold for £475.

An obituary of Thomas Thorp (1850–1915) was published by the Royal Astronomical Society (available in full online). A history of the Manchester Astronomical Society by Duckworth describes Thorp as 'a scientific and mechanical genius'. The obituary notes that he was working on his own ruling engine design which obviated the use of fine screws and he is also noted for developing the first working 'coin in a slot' gas meter.

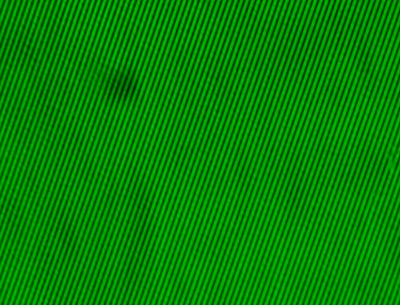

Under the microscope: Although the grating's supporting glass plate thickness of 5 mm is not ideal for studying under the microscope, unlike microscope test slides with demanding ruled engine lines, the 14 500 lines per inch grating i.e. a spacing of 1.75 microns is an undemanding subject for the optical microscope; a typical 10X NA0.25 objective should readily resolve the lines. The spacing seems common for modern gratings and dependent on the required diffraction spectra desired for a given wavelength of light.

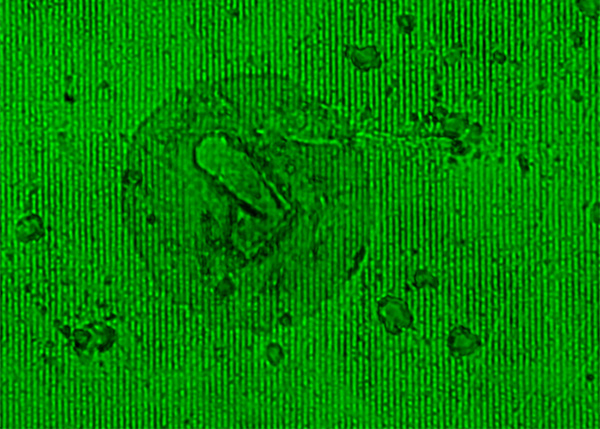

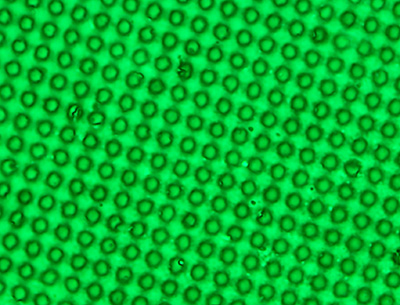

The Rowland replica grating under the microscope. Zeiss 16X NA0.4 (Optovar 2X), transmitted brightfield with green filter (objective is lack of coverslip tolerant). The darker disc is a dust particle underneath the grating layer. The frequency is very even and rulings very straight. The lines are not contiguous and frequently interrupted; the author is uncertain if this affects its performance as a grating cf a master (although CDs with digital data are essentially the same interrupted lines when used as a grating.).

As the image illustrates, this uncovered replica is very prone to dirt and scuffing.

The thickness of the plate (5 mm) precluded use of transmitted contrast enhancement techniques such as phase and DIC.

Compared with modern 'demonstration quality' gratings: A browse around the web suggests that replica gratings are still the cost effective method for many scientific applications. 'Edmund Optics' describes how their modern 'master gratings' are made from 'interferometrically-controlled ruling engines' using a 'very fine diamond tool' from which their replicas are made. High quality mounted replica gratings are quite expensive but the enthusiast of physics can buy demonstration quality gratings as used in education for a few pounds each. These are so-called 'embossed holographic optical elements' (HOE) using plastic film and are typically mounted in a 35 mm film sized card. Wikipedia has a short entry on how such items are made and seems to be the same sort of technology as used for holograms on credit cards etc.

The set above with three gratings 500, 100 linear lines/mm and 13 500 two axis lines/in (532 lines/mm) plus red laser / white LED light (a keyfob) sells for £10 on eBay (UK). The seller describes the gratings as "highly efficient embossed Holographic Optical Elements (H.O.E.). The quality of the spectrum produced from these gratings is the brightest possible with the minimum of distracting visual noise."

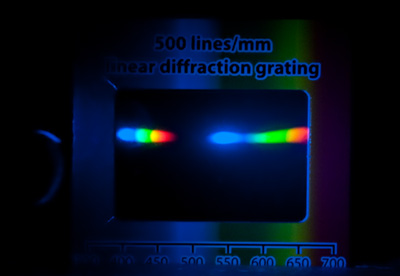

Modern replica gratings in use compared with the Rowland replica grating:

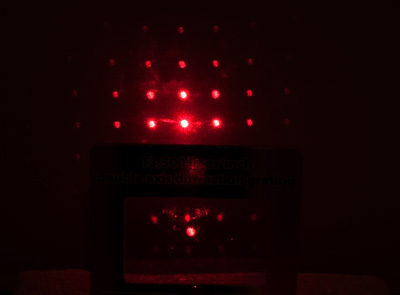

Monochromatic red laser 650nm transmitted through the modern gratings to observe projected diffraction pattern, under same conditions.

Left, 500 lines/mm, middle 1000 lines/mm, right 13 500 two axis lines/in (531 lines/mm). (The laser is in foreground, grating slide is central showing laser spot, and image projected onto white paper upper half of image.)

The much closer pattern spacings of the 532 lpm double axis grating than the 500 lpm suggests the former does not have the ruling spacing declared, see below.

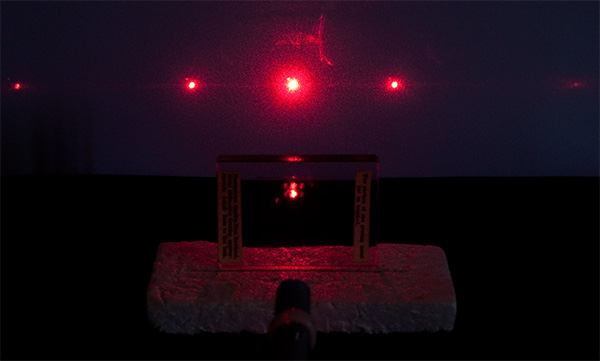

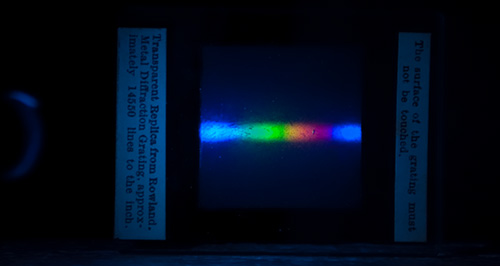

Monochromatic red laser 650nm transmitted through the Rowland grating to observe projected diffraction pattern. Its declared 14 550 lines / inch, i.e. 573 lines /mm, gives a similar spectra to the modern 500 lines/mm grating (left above).

Spectra from the white LED torch supplied shining at a glancing angle from front left. The 500 lines/mm grating is able to show a first and second order spectra in the field shown; the Rowland grating shows the first order. The finely spaced data on e.g. CD-ROMS can also be used to demonstrate some properties of diffraction gratings.

Modern gratings under the microscope: A circular punch a few mm diameter cuts out flat samples to mount dry under a coverslip on a microscope slide.

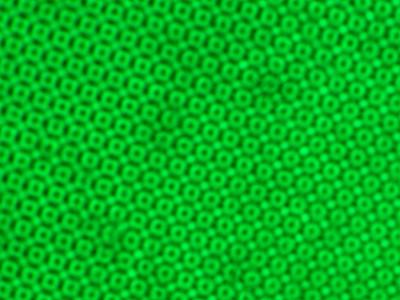

Modern linear diffraction gratings under the microscope. Left 1000 lines/mm, right 500 lines/mm. Zeiss 40X NA0.75 objective, green transmitted brightfield with oblique. Unlike the Rowland replica grating, these have contiguous lines. None of the gratings seem to respond well to DIC.

Measuring the rulings under the microscope calibrated with a stage micrometer give close agreement with the stated lines per mm.

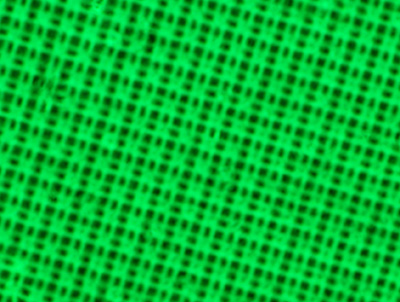

Modern double axis diffraction grating 13 500 lines/in (i.e. should be a spacing 1.88 µm) under the microscope. An area at edge with scratch suggests that the grating is supported on a substrate. Zeiss 40X NA0.75 objective, brightfield and green filter with slight oblique.

Phase contrast at different focus planes, left - below focus plane, middle - at focus, right - above focus. Modern double axis diffraction grating 13 500 lines/in under the microscope. Zeiss 40X NA0.75 objective, brightfield phase and green filter with slight oblique.

This double axis grating with phase contrast gave cross-eyed inducing geometrical patterning effects above and below the focus plane.

Rather curiously this grating from careful calibration of the microscope is actually ca. 201 lpm or ca. 5112 lpi, much lower than stated and at the same mag is clearly coarser than the 500 lpm when it should be similar at 531 lpm. This is also consistent with the diffraction pattern above as the pattern spacing decreases with increased diffraction rulings spacings.

A chance purchase on eBay certainly prompted a fascinating browse through the literature to learn about the replica grating's history, the people associated with 19th / early 20th century grating manufacture and also an exploration under the microscope of diffraction gratings both antique and modern—as well as revisiting some school level classic physics experiments. The modern grating examples, given their cheapness and high quality, may be useful as test objects and for contrast enhancement studies for lower to mid powers.

Comments to the author David Walker are welcomed.

Updated Nov. 28th 2016.

References and additional resources

B Bracegirdle, 'Notes on Modern Microscope Manufacturers', Quekett Microscopical Club, London, 1998, p.12.

A V Howard, 'Chamber's Dictionary of Scientists', London, 1964 reprint, p.390.

Thomas Thorp, 'A Note on Diffraction Grating Replicas', Popular Astronomy, 1906, vol. 14, pp.93-96. (Link is to complete paper.)

Robert J Wallace, 'Diffraction Grating Replicas', Astrophysical Journal, 1905, vol. 22, pp.123-130. (Link is to complete paper.)

Robert J Wallace, 'Diffraction Grating Replicas. Second Note.', Astrophysical Journal, 1906, vol. 23, pp.96–99. (Link is to complete paper.)

A Grating Ruling Engine - Brian Manning's article on the British Astronomical Association website (first published in 'Amateur Scientist', Scientific American, April, 1975'), describes how he developed in his spare time over many years a sophisticated ruling engine using modern techniques and capable of producing the highest quality gratings.

Published in the April 2011 edition of Micscape.

Please report any Web problems or offer general comments to the Micscape Editor .

Micscape is the on-line monthly magazine of the Microscopy UK web site at Microscopy-UK

©

Onview.net Ltd, Microscopy-UK, and all contributors 1995

onwards. All rights reserved.

Main site is at

www.microscopy-uk.org.uk

with full mirror

at

www.microscopy-uk.net

.