Please note, if you require in-depth technical details on any aspect of hard drives, a manufacturers web site may be able to provide the info'. The author is a hobbyist of macro-photography but not a technical expert!

When my brother's computer hard disc drive failed for good recently, it gave me an opportunity to pull one apart, which I've been eager to do for some time. I've always been fascinated by engineering and electronics on a macroscopic or microscopic scale and the Home in Close-Up series describes some other interesting man-made subjects for the stereo microscope that can be found around the home.

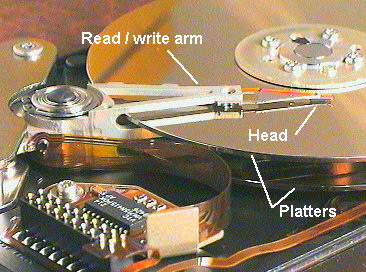

You often see photos of opened hard disc drives in computer magazines showing the one or more magnetic platters and read/write arms, but I was particularly keen to take a close look at the read/write heads, which 'chug' away day after day in our PC's reading and writing data.

In case it needs to be said, only dismantle a hard drive that is irrepairable, unwanted and which has no valuable data on it. Breaking the seal will invalidate the warranty and expose the drive to dust and damp air which will ruin it.

(An aside: If you have an older working hard drive that is just redundant e.g. because of drive capacity, it's worth reviewing options for its continued use. They can be useful as a backup drive of critical data for your own PC, or perhaps sold on if not needed. Older smaller drives if reformatted and in good condition, are often in high demand by owners of older computers who want a lower capacity hard drive that can't be sourced new).One of the first things that struck me when dismantling the drive, is how well engineered they are, which is perhaps not surprising given the demands placed on the drive when in use and the fine tolerances required for them to work effectively.

In

principle a hard drive is fairly simple. In a typical older hard drive,

a motor spins a central shaft at 3600 rpm, although many drives now spin

at higher speeds such as 5400, 7200 or even 10 000 rpm. On the shaft are

mounted a number of magnetic platters (the 'disk pack') , the higher capacity

drives having more platters. The one I dismantled was a 540MB drive and

had two platters (each ca. 95mm diameter and 1mm thick) shown in the image

right.

In

principle a hard drive is fairly simple. In a typical older hard drive,

a motor spins a central shaft at 3600 rpm, although many drives now spin

at higher speeds such as 5400, 7200 or even 10 000 rpm. On the shaft are

mounted a number of magnetic platters (the 'disk pack') , the higher capacity

drives having more platters. The one I dismantled was a 540MB drive and

had two platters (each ca. 95mm diameter and 1mm thick) shown in the image

right.

An actuator mechanism (seen far left of image above) moves the stacked read/write arms across the platter surfaces in an arc. There were three read/write heads on this drive, one on each side of the upper platter and one reading the top side of the lower platter. If you've ever wondered what the hard drive specification called 'cylinder' means that may appear during the computer boot-up sequence, it's now easy to appreciate. A 'cylinder' is the collection of tracks forming an imaginary cylinder beneath the read/write heads for a given position of the read/write arm.

According to ref. 1, in operation the tiny read/write heads on the end of each arm don't actually touch the platter surfaces, they ride on a cushion of air typically 0.25 - 0.65 micrometres thick (a micrometre is one thousandth of a millimetre). I noted when the heads are stationary that they do touch the surface in this drive, presumably they ride up when the disc spins. The very close working tolerances is partly why the hard drive has to be hermetically sealed, as tiny dust particles or any hint of condensation would interfere with its reliable operation. When I dismantled the drive there was a small woven pad enclosed, possibly a drying agent, to remove last traces of moisture.

The

damage often incurred on a hard drive (e.g. the 'bad sectors' reported

by software) is sometimes caused by the heads damaging the surface e.g.

when the computer is handled while the drives are running. Modern drives

'park' the heads in unused areas of the platters when the PC is switched

off to minimise this sort of damage.

The

damage often incurred on a hard drive (e.g. the 'bad sectors' reported

by software) is sometimes caused by the heads damaging the surface e.g.

when the computer is handled while the drives are running. Modern drives

'park' the heads in unused areas of the platters when the PC is switched

off to minimise this sort of damage.

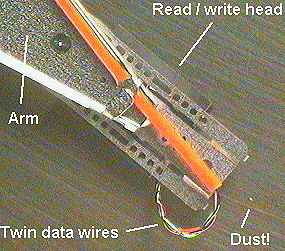

A close-up of the head at the end

of the arm is shown left. The head itself is the black rectangle below

the metal support. For scale the black read/write head is ca. 2.8 x 2.25

mm.

It

was the head in particular I wanted a close look at, to study their construction

and operation. I suspected there ought to be some sort of coil attached

to the twin data wires shown above, if so it would be of minute dimensions!

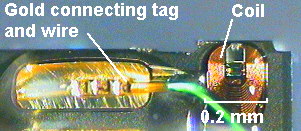

I wasn't disappointed - by viewing the end of the thin head a tiny coil

barely 0.2mm across was visible (shown right). The concentric turns of

wire making up the coil (just visible right as copper coloured rings) were

even more impressive, as they were estimated to be 0.014mm in diameter

(i.e. about one tenth of the thickness of a typical human hair!). It's

difficult to judge under an optical microscope whether this was a mechanically

assembled wire coil, or a 'coil' etched on a printed circuit board. Nevertheless,

manufacturing and assembling these heads is an engineering marvel. Note

in the end view of the head shown above that the central part of the head

is slightly recessed.

It

was the head in particular I wanted a close look at, to study their construction

and operation. I suspected there ought to be some sort of coil attached

to the twin data wires shown above, if so it would be of minute dimensions!

I wasn't disappointed - by viewing the end of the thin head a tiny coil

barely 0.2mm across was visible (shown right). The concentric turns of

wire making up the coil (just visible right as copper coloured rings) were

even more impressive, as they were estimated to be 0.014mm in diameter

(i.e. about one tenth of the thickness of a typical human hair!). It's

difficult to judge under an optical microscope whether this was a mechanically

assembled wire coil, or a 'coil' etched on a printed circuit board. Nevertheless,

manufacturing and assembling these heads is an engineering marvel. Note

in the end view of the head shown above that the central part of the head

is slightly recessed.

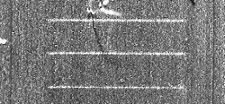

The

image left shows the surface of the head that skims each platter surface

(i.e. the read/write arm shown left above has been removed and turned upside

down). This revealed another intriguing feature, there were three finely

scored parallel lines, 0.8mm long and 0.2mm apart. The white blurred object

above the top line and white speck far left is dust, again emphasising

how dust can severely hinder the operation of the read/write head at this

scale.

The

image left shows the surface of the head that skims each platter surface

(i.e. the read/write arm shown left above has been removed and turned upside

down). This revealed another intriguing feature, there were three finely

scored parallel lines, 0.8mm long and 0.2mm apart. The white blurred object

above the top line and white speck far left is dust, again emphasising

how dust can severely hinder the operation of the read/write head at this

scale.

Without sectioning the read/write head, it is difficult to judge how the coil is related to these score lines and exactly how the head reads/writes data (see ref. 5 below for info' on this). In principle, the digital data is stored on the platters in tracks as changes in magnetisation of tiny areas of the magnetic coating. As these pass beneath each head in read mode, a digital signal is induced in the head mimicking the binary data stored on the disc. This data is fed via the twin data wires to the drive electronics. In write mode the binary data is sent to the head as a digital signal, which induces changes in the magnetisation of the disc coating and lays down this information on the disc in tracks. Speculating, the scored lines may be similar to the fine gap in an audiotape recorder playback head, i.e. they may be for want of a better term the 'point of focus' for the data read/write operation.

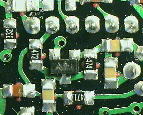

The

electronic circuit boards of the hard drive also makes extensive use of

surface

mount components - the tiny coloured rectangles barely a few mm across

shown in the image left. These have replaced the larger versions of discrete

components such as resistors, capacitors, diodes etc. found in many consumer

items where space and weight is at a premium e.g. mobile phones. Learn

more about these in the 'Microscopy

in the Home' Series.

The

electronic circuit boards of the hard drive also makes extensive use of

surface

mount components - the tiny coloured rectangles barely a few mm across

shown in the image left. These have replaced the larger versions of discrete

components such as resistors, capacitors, diodes etc. found in many consumer

items where space and weight is at a premium e.g. mobile phones. Learn

more about these in the 'Microscopy

in the Home' Series.

So ... if you thought hard drives were boring bits of kit buried away in your PC, I hope I've passed on some of my own enthusiasm for one of the many unseen miniature engineering and electronic marvels in many homes and offices which aren't always appreciated!

Comments to the author Dave

Walker welcomed.

| Please note that the above article was written as a hobbyist interested in macroscopy. I'm not an expert in hard drives and can't provide any technical info', advise on their repair or on file recovery from damaged drives. The hard drive manufacturers' web sites will have a wealth of information and troubleshooting advice. |

Related articles. The author has also written an illustrated article describing a macroscopic and microscopic tour around an empty inkjet cartridge.

References and Further Reading

1) Microsoft 'Encarta' multimedia encyclopaedia, under 'Hard Disk'.

2) 'Encyclopaedia Britannica', 15th Edition, under 'Computers', vol. 16, p.644 and 'Magnetic recording', vol. 7, p. 682.

3) 'The 386/486 PC' by H. Fairhead. I/O Press (UK), 2nd Edition, 1992, chapter 6. (Other books on the technology of computers should also have a section on the principles of a hard drive).

4) For technical details on hard drives and related technologies have a browse around some of the hard drive makers web sites. Most makers web addresses take the form of 'www.makersname.com'.

5) A terrific on-line resource describing how many parts of a PC and related technology work, with links to further resources is the PC Technology Guide.

Disclaimer: No responsibility is

accepted by the author or other contributors to Micscape, Microscopy UK

or Onview.net Ltd for damage to property, loss of data or injury caused

by disassembling a hard drive. It is up to the reader to take appropriate

care and to judge whether a hard drive is irretrievably broken and to ensure

that all valuable data has been removed/copied to other media.